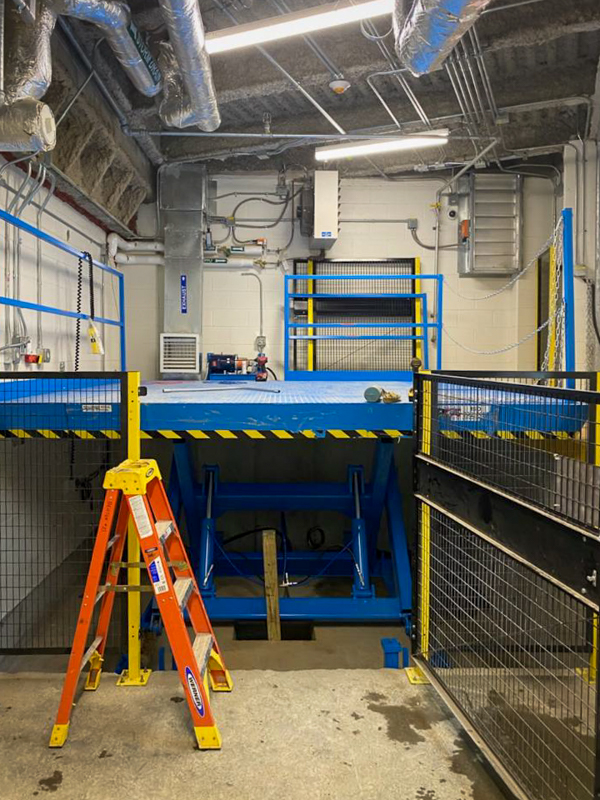

Dock Leveler Pits – A Confined Space Requiring Two Technicians

Almost 20 years ago, OSHA’s director of enforcement programs, Richard Fairfax, took the time to elaborate on the confined space policy that requires two people be present whenever a dock leveler pit is being inspected, or repair/installation work is being performed.

Almost 20 years ago, OSHA’s director of enforcement programs, Richard Fairfax, took the time to elaborate on the confined space policy that requires two people be present whenever a dock leveler pit is being inspected, or repair/installation work is being performed.

In December of 2002, Mr. Fairfax had received a letter in which Mr. Art Varga questioned whether a dock leveler pit should be considered a confined space or not. Fairfax provided a detailed reply that can be seen below.

In typical OSHA fashion, Fairfax never gave a firm yes/no answer, but clearly eluded to all three aspects that would cause an inspector to call out a dock leveler pit as a confined space. “From the manufacturer literature you enclosed with your letter it appears that a dock leveler pit could meet each of the above criteria and hence be a confined space.”, wrote Fairfax. OSHA has perfected the art of not answering questions outright, but rather suggesting what problems may be present. OSHA does this so they can change or reinterpret the protocols and standards whenever a new issue arises, and therefore does not lock themselves into any one rule, but rather allows them to find fault with any unsafe situation, whether they have addressed the exact situation previously or not.

In the reply letter shared below, you’ll see that OSHA essentially tells Mr. Varga that a dock leveler pit meets all 3 criteria for a Confined Space, but whether or not it would be a permit required confined space vs, and non-permit required confined space is to be determined by a number of factors at the specific location.

If you’re a customer of Beaton Industrial, rest assured that we always send two service technicians to complete our dock leveler pit work. We do this not only for the safety of our service technicians, but for the safety and liability of our customers. Ultimate responsibility for the safety of people on-site resides with the property owner. There is good reason why so many company’s have hired in-house safety managers in the last decade, just one accident can cripple an entire business.

There are too many possible scenarios that could unfold while a technician is under the dock leveler board, and almost all of them can result in serious injury, or even death.

If your company has been allowing a subcontractor to inspect your dock levelers with just one technician present, now is the time to demand they send two technicians, not only to stay in compliance with OSHA standards, but more importantly, potentially save a human life.

Take a moment to review the 2002 OSHA reply to Mr. Varga below. If you have any questions regarding this policy, or would like to schedule an OSHA compliant dock leveler inspection, please contact us.

December 2, 2002

Mr. Art Varga

Materials Handling Equipment Company

1740 West 13th Avenue

Denver, Colorado 80204

Dear Mr. Varga:

Thank you for your July 1 letter to the Occupational Safety and Health Administration’s (OSHA’s) Englewood Area Office in Englewood, Colorado. Your letter has been referred to the Directorate of Enforcement Programs’ (DEP’s) Office of General Industry Enforcement for an answer to your questions regarding permit-required confined spaces. Your questions have been restated below for clarity.

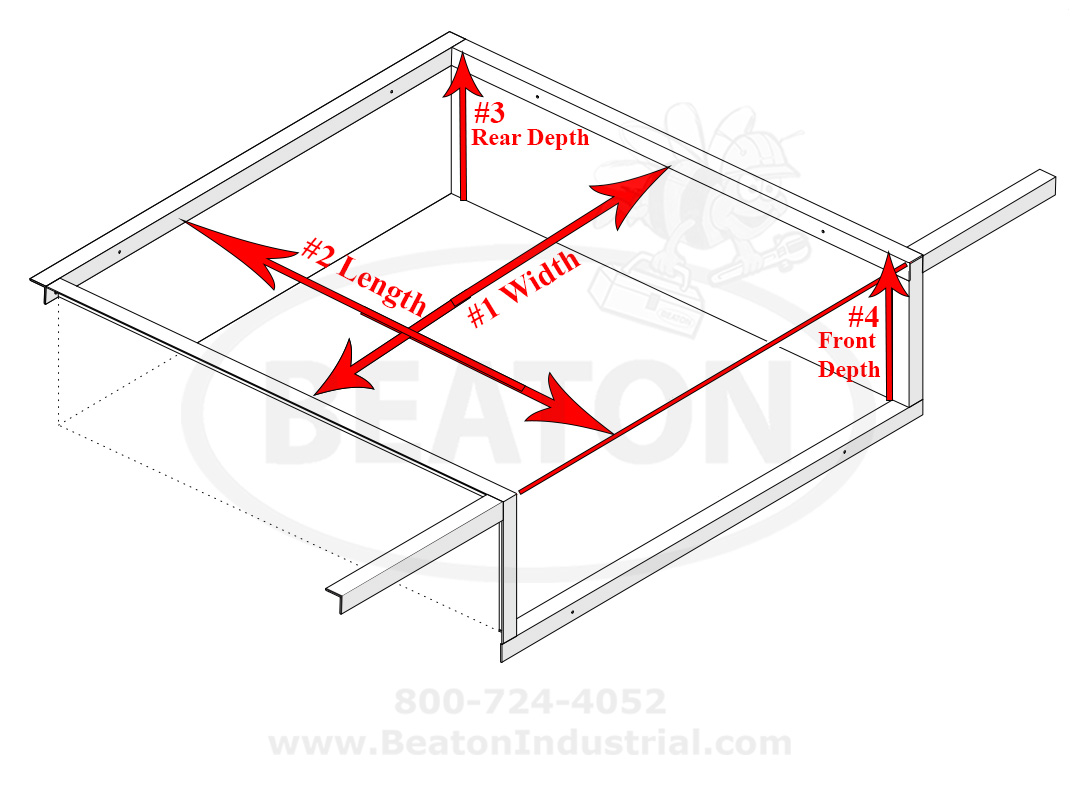

Question 1: Are dock leveler pits confined spaces?

Reply: Dock leveler pits could be confined spaces. A confined space means a space that:

(1) Is large enough and so configured that an employee can bodily enter and perform assigned work; and

(2) Has limited or restricted means for entry or exit (for example, tanks, vessels, silos, storage bins, hoppers, vaults, and pits are spaces that may have limited means of entry.); and

(3) Is not designed for continuous employee occupancy.

From the manufacturer literature you enclosed with your letter it appears that a dock leveler pit could meet each of the above criteria and hence be a confined space.

Question 2: If a dock leveler pit is a confined space would a permit be required?

Reply: That would depend on whether the dock leveler pit was a Permit-required confined space. A permit-required confined space means a confined space that has one or more of the following characteristics:

(1) Contains or has a potential to contain a hazardous atmosphere;

(2) Contains a material that has the potential for engulfing an entrant;

(3) Has an internal configuration such that an entrant could be trapped or asphyxiated by inwardly converging walls or by a floor which slopes downward and tapers to a smaller cross section; or

(4) Contains any other recognized serious safety or health hazard.

It appears from your literature that there could be mechanical, electrical, or other hazards within the dock leveler pit that could trigger the permit-required confined space designation. If the dock leveler pit was determined to be a permit-required confined space, an entry permit, along with all of the other required provisions of §1910.146 for permit space entry would have to be followed during entry.

However, a space classified as a permit-required confined space may be reclassified as a non-permit confined space under the following procedures:

(1) If the permit space poses no actual or potential atmospheric hazards and if all hazards within the space are eliminated without entry into the space, the permit space may be reclassified as a non-permit confined space for as long as the non-atmospheric hazards remain eliminated.

(2) If it is necessary to enter the permit space to eliminate hazards, such entry must be performed under paragraphs 1910.146(d) through 1910.146(k). If testing and inspection during that entry demonstrate that the hazards within the permit space have been eliminated, the permit space may be reclassified as a non-permit confined space for as long as the hazards remain eliminated.

(3) The employer must document the basis for determining that all hazards in a permit space have been eliminated, through a certification that contains the date, the location of the space, and the signature of the person making the determination. The certification must be made available to each employee entering the space or to that employee’s authorized representative.

(4) If hazards arise within a permit space that has been declassified to a non-permit space under 1910.146(c)(7), each employee in the space must exit the space. The employer must then reevaluate the space and determine whether it must be reclassified as a permit space, in accordance with other applicable provisions of this section.

Therefore, if the dock leveler pit only contains electrical and mechanical hazards that can be eliminated through lockout/tagout procedures, then the space may be reclassified as a non-permit required confined space during the period in which the lockout/tagout procedures are in effect in accordance with the conditions stated above. Lockout/tagout procedures cannot, however, serve to permanently reclassify the dock leveler to a non-permit confined space status unless the dock leveler is permanently locked out.

Thank you for your interest in occupational safety and health. We hope you find this information helpful. OSHA requirements are set by statute, standards, and regulations. Our interpretation letters explain these requirements and how they apply to particular circumstances, but they cannot create additional employer obligations. This letter constitutes OSHA’s interpretation of the requirements discussed. Note that our enforcement guidance may be affected by changes to OSHA rules. Also, from time to time we update our guidance in response to new information. To keep apprised of such developments, you can consult OSHA’s website at http://www.osha.gov. If you have any further questions, please feel free to contact the [Office of General Industry Enforcement] at (202) 693-1850.

Sincerely,

Richard E. Fairfax, Director

Directorate of Enforcement Programs