INDUSTRIAL MEZZANINE LIFT INSTALLATION

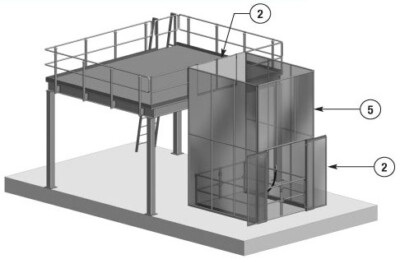

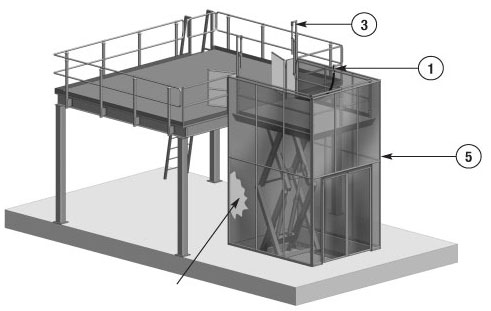

REQUIREMENTS FOR RIDER/OPERATOR MEZZANINE LIFTS

1. Lift control is a constant pressure push button with a 20 foot coil cord mounted on the platform which allows the rider/operator to be in constant control of vertical movement. Automatic (send/call) systems are not allowed with riders.

2. The 42″ high guard rail gate on the mezzanine table and all enclosure doors are interlocked so that they can not be opened unless the lift is present and any open door or gate prevents lift movement.

3. The 42” high guard rails with mid rails and 4” toe boards mounted on the platform are equipped with vertical folding gates for access and the gates are electrically interlocked so they must be closed to allow lift movement.

4. The face of the mezzanine adjacent to the lift must be covered with a smooth surface from ground to top of guard rail to eliminate shear points. Windows and or interlocked doors are optional.

5. The pit is enclosed on all sides not against a wall or smooth facia, with a mesh enclosure that extends upward to the top of the guard rail on the fully raised lift. Lower level access gates on the enclosure shall be interlocked so that they cannot be opened unless the lift is present and open gate will prevent lift movement.

Preproduction layout drawings will be available after receipt of order for preapproval by local authorities and we are pleased to assist in the code review process.

The guarding and control requirements for all mezzanine scissors lift platforms are outlined in ANSI 29.1:2012 and it should be noted that this code has been approved for inclusion in the next printing of the “International Building Code” which is scheduled for 2015 Copies of the ANSI code can be purchased from the Material Handling Institute online@mhi.org under the heading of publications.

Access Lift in Lowered Position

Access Lift in Raised Position

Two Scissor Lift Models to Choose From

“Big Friggin Lift” (BFL) Series Lift Tables

1 Year Parts & Labor/10 Year Structural Warranty

The BFL series lifts were designed for the high travel applications that also require large platforms. These hydraulic lift platforms are designed to move multiple pallets or large loads up a floor level or to high mezzanines. These big lifts are all built with tubular steel legs to maximize the rigidity of the unit and to minimize the weight. Inquire about these mechanical lift tables today.

BFL Features and Benefits

- These units are equipped with the patented “Platform Centering Device”.

- All of the controllers are assembled in our UL listed panel shop.

- These units are fully primed and finished with a baked enamel finish.

- The cylinders are machine grade with return lines.

- The oil reservoirs are mild steel for long life.

- These units conform to all applicable ANSI codes.

- All pressure hoses are double wire braid with JIC fittings.

- Two bi parting electrically interlocked folding gates are optional.

- A manual lowering valve is standard.

Multi Stage (MSL) Series Lift Tables

1 Year Parts and Labor & 10 Year/250,000 Cycle Warranty

The MSL Series lifts were designed for the higher travel applications that require shorter platform lengths than would be available with a single scissor lift design. The lighter capacity units are built with solid steel legs for more compact design and greater cost savings, while the higher capacity units are built with structural tubing legs for greater rigidity, lighter weight and optimum cost savings. Inquire about these multi stage scissor lift platforms today.

MSL Features and Benefits

- These units are equipped with the patented “Platform Centering Devices”, which doubles or triples lift life.

- All of the controllers are Underwriter Laboratory listed assemblies.

- These units are fully primed and finished with a baked enamel finish.

- The cylinders are machine grade with clear plastic return lines.

- All pressure hoses are double wire braid with JIC fittings.

- The reservoirs are mild steel.

- These hydraulic lifting platforms conform to all applicable ANSI codes.

Big Friggin Lift (BFL) Standard Sizes

| Model | Travel ft | Capacity | Std. Min. Platform | Opt. Max. Platform | Max. End | Loading Side | Baseframe Size | Lowered Height | Raised Height | Speed Sec. | Motor H.P. | Ship Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BFL2-2120 | 10 | 2000 | 6 x 8 | 8 x 10 | 2000 | 1325 | 66 x 90 | 1′ 3-1/2″ | 11′ 3-1/2″ | 47 | 5 | 2607 |

| BFL2-4120 | 10 | 4000 | 6 x 8 | 8 x 10 | 2150 | 1325 | 66 x 90 | 1′ 3-1/2″ | 11′ 3-1/2″ | 47 | 5 | 2607 |

| BFL2-6120 | 10 | 6000 | 6 x 8 | 8 x 10 | 3150 | 1825 | 66 x 90 | 1′ 5-1/2″ | 11′ 5-1/2″ | 45 | 5 | 2653 |

| BFL2-2144 | 12 | 2000 | 6 x 9 | 8 x 11 | 2000 | 1325 | 66 x 102 | 1′ 5-1/2″ | 13′ 5-1/2″ | 45 | 5 | 3085 |

| BFL2-4144 | 12 | 4000 | 6 x 9 | 8 x 11 | 2550 | 1325 | 66 x 102 | 1′ 5-1/2″ | 13′ 5-1/2″ | 45 | 5 | 3085 |

| BFL2-6144 | 12 | 6000 | 6 x 9 | 8 x 11 | 3500 | 1925 | 66 x 102 | 1′ 5-1/2″ | 13′ 5-1/2″ | 54 | 5 | 3767 |

| BFL3-2180 | 15 | 2000 | 6 x 8 | 8 x 10 | 2000 | 1200 | 66 x 90 | 2′ – 1/4″ | 17′ 1/4″ | 54 | 5 | 3930 |

| BFL3-4180 | 15 | 4000 | 6 x 8 | 8 x 10 | 2650 | 1200 | 66 x 90 | 2′ – 1/4″ | 17′ 1/4″ | 54 | 5 | 3930 |

| BFL3-6180 | 15 | 6000 | 6 x 8 | 8 x 10 | 4000 | 1950 | 66 x 90 | 2′ 2-1/2″ | 17′ 2-1/2″ | 65 | 5 | 3990 |

| BFL3-2216 | 18 | 2000 | 6 x 10 | 8 x 12 | 2000 | 1025 | 66 x 114 | 2′ 2-1/2″ | 20′ 2-1/2″ | 62 | 5 | 5065 |

| BFL3-4216 | 18 | 4000 | 6 x 10 | 8 x 12 | 2650 | 1025 | 66 x 114 | 2′ 2-1/2″ | 20′ 2-1/2″ | 62 | 5 | 5065 |

| BFL3-6216 | 18 | 6000 | 6 x 10 | 8 x 12 | 4000 | 2650 | 66 x 114 | 2′ 8-1/2″ | 20′ 8-1/2″ | 64 | 5 | 6954 |

Multi Stage Lift (MSL) Standard Sizes

| Model | Travel | Capacity | Std Min Platform | Opt. Max. Platform | Maximum End | Loading Side | Baseframe Size | Lowered Height | Raised Height | Speed Sec. | Motor H.P. | Ship Wt. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MSL2-248 | 48 | 2000 | 30 X 42 | 48 X 66 | 1500 | 1500 | 30 X 42 | 10-1/2 | 58-1/2 | 16 | 2 | 750 |

| MSL2-448 | 48 | 4000 | 30 X 42 | 48 X 66 | 2800 | 2800 | 30 X 42 | 12-1/2 | 60-1/2 | 25 | 2 | 875 |

| MSL2-648 | 48 | 6000 | 30 X 42 | 48 X 66 | 3800 | 3800 | 30 X 42 | 13-1/2 | 61-1/2 | 37 | 2 | 1150 |

| MSL2-260 | 60 | 2000 | 30 X 48 | 48 X 72 | 1400 | 1400 | 30 X 48 | 10-1/2 | 70-1/2 | 20 | 2 | 850 |

| MSL2-460 | 60 | 4000 | 30 X 48 | 48 X 72 | 2500 | 2500 | 30 X 48 | 12-1/2 | 72-1/2 | 32 | 2 | 975 |

| MSL2-660 | 60 | 6000 | 30 X 48 | 48 X 72 | 3400 | 3400 | 30 X 48 | 13-1/2 | 73-1/2 | 44 | 2 | 1250 |

| MSL2-272 | 72 | 2000 | 30 X 54 | 48 X 78 | 1100 | 1100 | 30 X 54 | 10-1/2 | 82-1/2 | 23 | 2 | 925 |

| MSL2-472 | 72 | 4000 | 30 X 54 | 48 X 78 | 2400 | 2400 | 30 X 54 | 12-1/2 | 84-1/2 | 37 | 2 | 1075 |

| MSL2-672 | 72 | 6000 | 30 X 54 | 48 X 78 | 3000 | 3000 | 30 X 54 | 13-1/2 | 85-1/2 | 52 | 2 | 1400 |

| MSL2-284 | 84 | 2000 | 38 X 60 | 56 X 84 | 1400 | 1400 | 38 X 60 | 12-1/2 | 96-1/2 | 27 | 2 | 1000 |

| MSL2-484 | 84 | 4000 | 38 X 60 | 56 X 84 | 2300 | 2300 | 38 X 60 | 14-1/2 | 98-1/2 | 44 | 2 | 1100 |

| MSL2-684 | 84 | 6000 | 38 X 68 | 56 X 92 | 3200 | 3200 | 38 X 68 | 16-1/2 | 100-1/2 | 66 | 2 | 1475 |

| MSL2-884 | 84 | 8000 | 48 X 65 | 66 X 89 | 4400 | 4400 | 48 X 65 | 18-3/4 | 102-3/4 | 41 | 5 | 2200 |

| MSL2-1084 | 84 | 10000 | 48 X 65 | 66 X 89 | 5200 | 5200 | 48 X 65 | 18-3/4 | 102-3/4 | 48 | 5 | 2250 |

| MSL2-1284 | 84 | 12000 | 48 X 72 | 66 X 96 | 6300 | 6300 | 48 X 72 | 22-3/4 | 106-3/4 | 52 | 5 | 2550 |

| MSL2-296 | 96 | 2000 | 38 X 66 | 56 X 90 | 1300 | 1300 | 38 X 66 | 12-1/2 | 108-1/2 | 31 | 2 | 1050 |

| MSL2-496 | 96 | 4000 | 38 X 66 | 56 X 90 | 2200 | 2200 | 38 X 66 | 14-1/2 | 110-1/2 | 49 | 2 | 1225 |

| MSL2-696 | 96 | 6000 | 38 X 72 | 56 X 96 | 3300 | 3300 | 38 X 72 | 16-1/2 | 112-1/2 | 71 | 2 | 1525 |

| MSL2-896 | 96 | 8000 | 48 X 71 | 66 X 95 | 4600 | 4600 | 48 X 71 | 18-3/4 | 114-3/4 | 45 | 5 | 2400 |

| MSL2-1096 | 96 | 10000 | 48 X 71 | 66 X 95 | 5400 | 5400 | 48 X 71 | 18-3/4 | 114-3/4 | 56 | 5 | 2675 |

| MSL2-1296 | 96 | 12000 | 48 X 74 | 66 X 98 | 6000 | 6000 | 48 X 74 | 22-3/4 | 118-3/4 | 58 | 5 | 2775 |

| MSL3-2108 | 108 | 2000 | 32 X 54 | 44 X 78 | 1100 | 1100 | 32 X 54 | 14 | 122 | 33 | 2 | 1000 |

| MSL3-4108 | 108 | 4000 | 32 X 58 | 44 X 82 | 2100 | 2100 | 32 X 58 | 20 | 128 | 55 | 2 | 1275 |

| MSL3-6108 | 108 | 6000 | 34 X 60 | 46 X 84 | 3700 | 3700 | 34 X 60 | 23 | 131 | 38 | 5 | 1800 |

| MSL3-2126 | 126 | 2000 | 32 X 62 | 44 X 86 | 1300 | 1300 | 32 X 62 | 17 | 143 | 62 | 2 | 1250 |

| MSL3-4126 | 126 | 4000 | 34 X 66 | 46 X 90 | 2400 | 2400 | 34 X 66 | 20 | 146 | 88 | 2 | 1500 |

| MSL3-6126 | 126 | 6000 | 36 X 68 | 48 X 92 | 3400 | 3400 | 36 X 68 | 23 | 149 | 60 | 5 | 2175 |

| MSL3-8126 | 126 | 8000 | 42 X 71 | 54 X 95 | 4000 | 4000 | 42 X 71 | 25-1/4 | 151-1/4 | 59 | 5 | 2425 |

| MSL3-10126 | 126 | 10000 | 42 X 71 | 54 X 95 | 5600 | 5600 | 42 X 71 | 25-1/4 | 151-1/4 | 69 | 5 | 2925 |

| MSL3-12126 | 126 | 12000 | 42 X 72 | 54 X 96 | 6200 | 6200 | 42 X 72 | 31-1/4 | 157-1/4 | 81 | 5 | 3200 |

| MSL3-2144 | 144 | 2000 | 32 X 72 | 44 X 96 | 1100 | 1100 | 32 X 72 | 17 | 161 | 69 | 2 | 1400 |

| MSL3-4144 | 144 | 4000 | 34 X 73 | 46 X 97 | 2100 | 2100 | 34 X 73 | 20 | 164 | 97 | 2 | 1650 |

| MSL3-6144 | 144 | 6000 | 36 X 74 | 48 X 98 | 3000 | 3000 | 36 X 74 | 23 | 167 | 65 | 5 | 2325 |

| MSL3-8144 | 144 | 8000 | 42 X 77 | 54 X 101 | 4400 | 4400 | 42 X 77 | 25-1/4 | 169-1/4 | 65 | 5 | 3150 |

| MSL3-10144 | 144 | 10000 | 42 X 77 | 54 X 101 | 5000 | 5000 | 42 X 77 | 25-1/4 | 169-1/4 | 84 | 5 | 3225 |

| MSL3-12144 | 144 | 12000 | 42 X 80 | 54 X 104 | 6000 | 6000 | 42 X 80 | 31-1/4 | 175-1/4 | 92 | 5 | 3850 |

Ready for a Quote?