Capacities & Lifts

Rated loads from 1/8, 1/4, 1/2, 1, & 2 ton. Available in standard lifts of 10, 15, and 20 feet. Other lifts available. Standard push button drop is 4-feet less than lift. CSA approved.

Available Voltages

115/230 – Single Phase; 230/460, 208, 380, 415, 575 Three Phase, 60 Hertz Standard, 50 Hertz Available

Two-Speed Hoist Models

Optional with 3 to 1 speed ratio, three-phase, single voltage only

Limit Switches

Adjustable to regulate upper and lower load travel. Brass nuts standard for improved repeatability and chain positioning.

Oil Bath Transmission

Precision machined alloy steel gears run in an oil bath for longer, quieter operation.

NEMA 3R Push Button Station

Ergonomic design fits operator’s hand for thumb or two-handed operation. 24 Volt Control for operator safety. 115 Volt control available upon request.

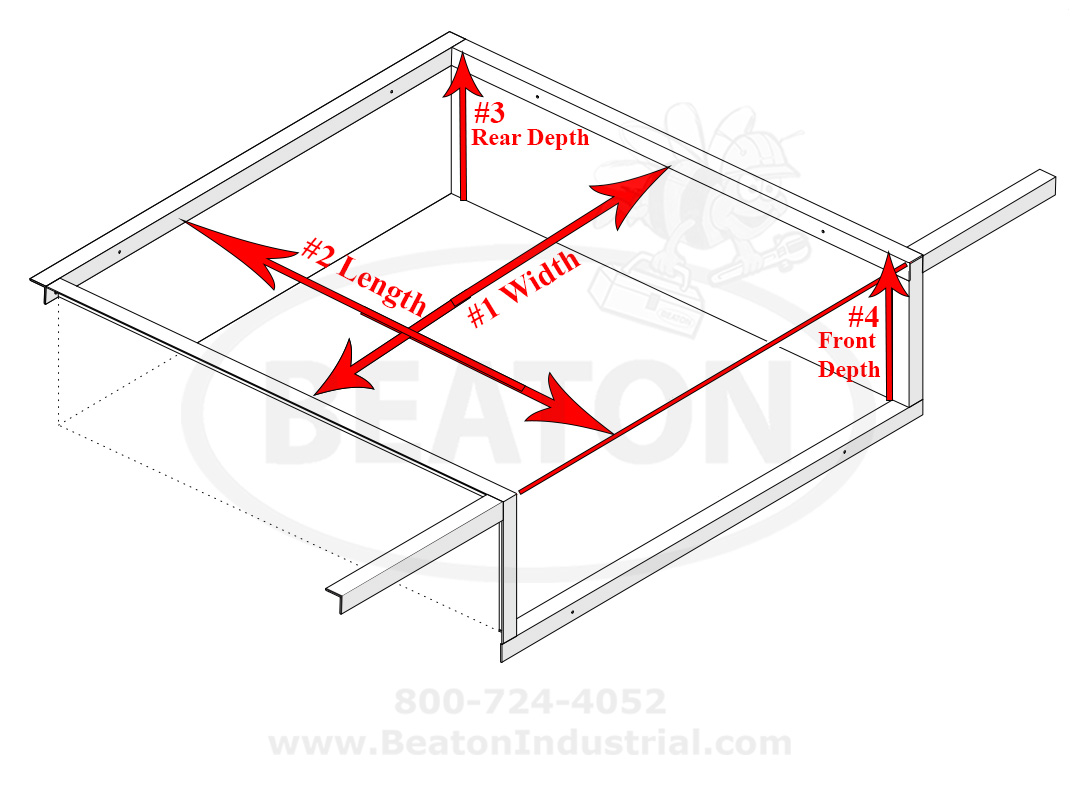

Frame

Compact aluminum housing for portability and ease of installation.

Accessories

Full line of accessories available, including Variable Frequency Drives.

Chain Container

Standard on lifts up to 20 ft. single chain / 10 ft. double chain.

Lifetime Warranty

Every hoist is throughly inspected and tested prior to shipment from the factory. Should any problem develop, return the complete hoist prepaid to your nearest Coffing Hoists Authorized Warranty Repair Station.

Models and Availability

| Capacity (lbs/Ton) | Lift Speed (fpm) | Model Number |

|---|---|---|

| 250 lbs | 1/8 Ton | 32 | JLC-0232 |

| 500 lbs | 1/4 Ton | 16 | JLC-0516 |

| 500 lbs | 1/4 Ton | 32 | JLC-0532 |

| 1000 lbs | 1/2 Ton | 16 | JLC-1016 |

| 1000 lbs | 1/2 Ton | 32 | JLC-1032 |

| 2000 lbs | 1 Ton | 16 | JLC-2016 |

| 4000 lbs | 2 Ton | 8 | JLC-4008 |

The Following are Standard Features Included on Every JLC Chain Hoist