Gantry Crane

Gantry Cranes come in a variety of models for various applications. Most common are the Fixed Height, and the Adjustable Height Gantry Crane. However, there are also portable gantry cranes made of lightweight aluminum for easy transport to the job site. Recent manufacturing improvements allow specific gantry cranes to be moved while the crane is under load*. (only available on models explicitly stating “movable under load”).

Fixed Height Gantries: Built to an exact height that cannot be altered. Used in repetitive lift applications.

Adjustable Gantries: Overall height of this gantry can be adjusted for differing applications. This allows the gantry to be used in a variety of factory locations. Adjustable height gantries are great for warehouses and machine welding shops.

Portable Gantries: Gantry crane that can be easily disassembled, moved to a job site, and reassembled by one or two workers. Great for construction companies, or service teams that are deployed to various job sites.

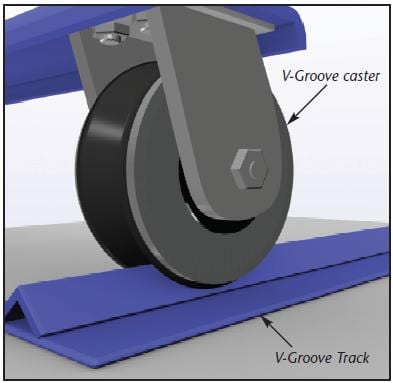

Track-Mounted Gantry Crane: Rides on an installed track that sits on the floor. Using a V-groove track and corresponding casters, this gantry moves only along the track route. End stops are installed to ensure the gantry does not roll off either end of the v-groove track. (see v-groove track pictures below)

Single Leg Gantry Crane: Ideal for maximizing floor space, and covering large building spans. This gantry crane has a leg on one end, and the other end attaches to an overhead runway.

Gantry Cranes provide an economical way to lift materials anywhere in a facility. The wheels enable movement the crane around the facility. A cost-effective lifting solution for areas of infrequent lifts, opposed to a more expensive permanent structure.

Fixed Height Gantry Crane

Fixed Height Gantry Crane

The fixed height gantry is the most common type of Gantry Crane. Fixed height gantries are a great economical lifting solution compared to an adjustable height crane. Applications that will benefit from a fixed height crane include processes that are predetermined and repetitive in nature. The fixed height gantry is mobile within the factory, and can be moved to different areas provided the necessary headroom is available. Though mobile, this unit is not easily portable. In contrast to the aluminum version, this crane would require a timely disassembly and reassembly to use off site.

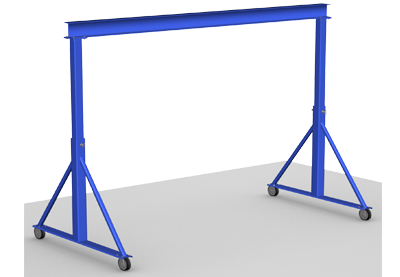

Adjustable Height Gantry Crane

Adjustable Height Gantry Crane

Adjustable height gantry cranes are multi-use and capable of altering their height to accommodate a particular lift. This is especially useful if one has a high lift in one room, and must get under a ceiling height to access another room in the factory. The typical height adjustment range is 3 feet in 6″ increments. Therefore, a 9′ minimum hub, has a 12′ maximum hub. Adjustment heights include 9’0″, 9’6″, 10’0″, 10’6″, 11’0″, 11’6″ and finally the max HUB of 12’0″. Standard adjustable height under boom options include 7′-10′, 9′-12′, 12′-15′, 15′-18′, and 17′-20′.

Aluminum Gantry Crane – Adjustable Height – Mobile, Portable

Aluminum Gantry Crane – Adjustable Height – Mobile, Portable

The Aluminum Gantry Crane is a mobile portable crane with adjustable height. Made from lightweight extruded aluminum for easy portability. Components can be easily lifted by one person. This allows for ease of use in variety of work areas and job sites. One of the more common applications is to carry the components up a ladder or staircase to a rooftop work area. In addition to the standard phenolic casters, inflatable pneumatic wheels are available for rough surfaces like gravel, and dry ground.

Adders and Optional Accessories for the Steel Gantry Crane

Casters — Molded phenolic casters with steel core’s are standard on all Gorbel steel gantry cranes.

Options for 1-2 ton Gantry Crane

- Urethane Casters with or without Cam Brake

- Four Position Swivel Locks

- Steel V-Groove Rigid Body

- Steel V-Groove Rigid Body with Cam Brake

Options for 3-5 ton Gantry Crane

- Urethane Casters with or without Cam Brake

- Four Position Swivel Locks without Cam Brake

- Steel V-Groove Rigid Body

End Stops

- Limit the travel of the trolley on the beam. End Stops are available in spans of 8′, 10′, 12′, 15′, 20′, 25′, and 30′ for all standard designs.

The Gorbel Fixed Height Gantry Crane is available in spans up to 30 feet and capacities up to 5 ton.

The Adjustable Steel Gantry can be moved to almost any location and can be easily adjusted to provide different lifting heights.

Fixed Length V-Groove Track

- Do you need your Gantry Crane to travel in a fixed path? Fixed length V-Groove Track allows your Gantry Crane to run in a straight line every time. Choose from single pin, or dual pin. Single pin is used for ending a V-Groove Track run. Dual pin is used for continuing a run. Standard V-Groove Track lengths are 10′, and 20′.

Aluminum Gantry Crane

A Lightweight, Adjustable, and Portable lifting solution

Lightweight

- Made from lightweight extruded aluminum track. Therefore, the components of the crane are easily lifted by one person. That is to say, the crane can be easily shipped to a job site. As well as, carried up ladder or staircase to a rooftop work area.

Adjustable Span & Height

- Top beam is secured to the supports by beam clamps, which can easily slide to fit any application.

- Adjustable height ensures a single ergonomic lifting solution for low headroom areas, and wider lift range in other areas.

Collapsible for easy storage

- Simple set up and break down. Collapse and store the gantry when not in use.

Options for the Aluminum Crane

- Capacities up to 2 Ton

- Standard Spans up to 20 feet

- Height Under Boom: 6-12′

- Top Running Trolley is included with unit

- Ratchet Adjusted Height is an optional adder

- Inflatable Pneumatic Wheels for Rough Surfaces is an optional adder

Gantry Crane – Catalog Download

Aluminum Gantry Crane – Catalog Download

Overhead Gantry Crane Design

Overhead crane design has remained relatively unchanged in recent years. However, the materials and manufacturing processes have changed greatly and for the better. Modern day cranes are being constructed in some of the most technologically advanced manufacturing facilities in the world. To speak with a sales representative about configuring a Gantry Crane for your application, or adding a Hoist to your system, please contact us. Jon@BeatonIndustrial.com – 800-724-4052.

Ease of Movement

- Firstly, the non marking durable phenolic casters provide low rolling resistance for easy movement.

- Additionally, the phenolic wheels roll smoothly, even over rough floor surfaces, and can withstand water, oil and most other chemicals.

- Lastly, An optional V-Groove caster and track is also available. More information on the V-groove track is below.

Safety

- Most importantly, the bolted beam to upright connection ensures that beam does not dislodge.

- Pre-engineered for use with powered hoists. A factor of 15% of the crane capacity is allowed for the hoist and trolley weight with an additional 25% of the capacity allowed for impact, thus allowing for maximum capacity use of the crane. For example, if it’s rated for 1000 lbs, it can safely lift 1000 lbs without having to worry about hoist weight or impact.